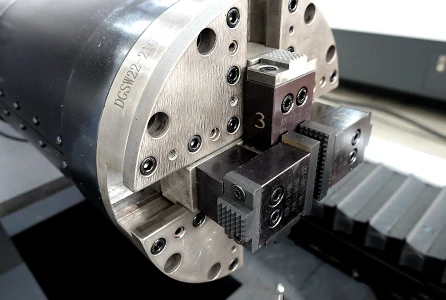

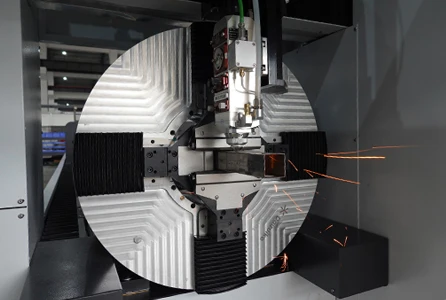

Pneumatic clamping, large and stable clamping force to ensure high-precision cutting;

Special support frame can avoid pipe sagging and deformation, improve cutting accuracy and prolong the service life of chuck

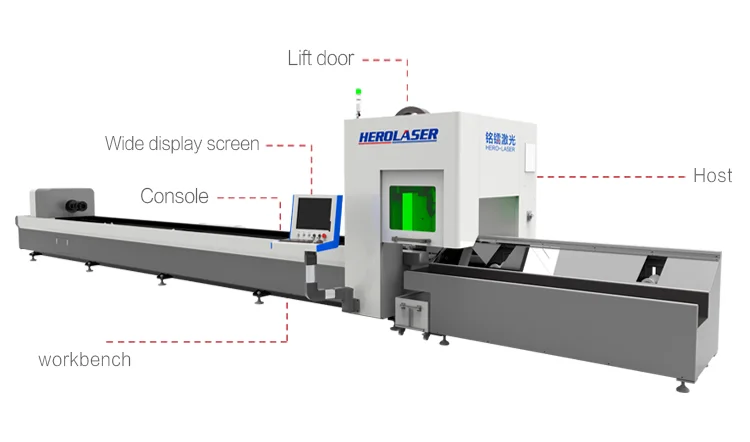

| Serial number | project | parameter |

|---|---|---|

| One | Equipment model | ML3015B |

| Two | Laser wavelength | 1070nm |

| Three | Maximum output power | 500W-3000W |

| Four | Effective cutting range | 3000mm×1500mm |

| Five | Cutting thickness | Apparent laser power and material |

| Six | Cutting speed | Apparent laser power and material |

| Seven | Positioning accuracy of worktable | ≤±0.05mm |

| Eight | Electricity demand | AC380V ± 5%/ 50Hz |

| Nine | Power consumption of the whole machine | ≤7.5KW |

| Ten | Cabinet size | 7750mm*2600mm*2170mm |

| Eleven | Load bearing of machine tool | 800KG |